10 In wet processing, two of the most commonly used methods are acid/alkali extraction–isoelectric precipitation and salt extraction (SE). However, the products of dry processing, the protein concentrates, are usually lower in protein content (up to 50–60% protein). The major advantages of dry processing are maintaining the functionality of native protein, lower energy and water use. 9 For complete separation of protein that still adheres to the starch granules, a second milling step is also used, which may increase the presence of damaged starch.

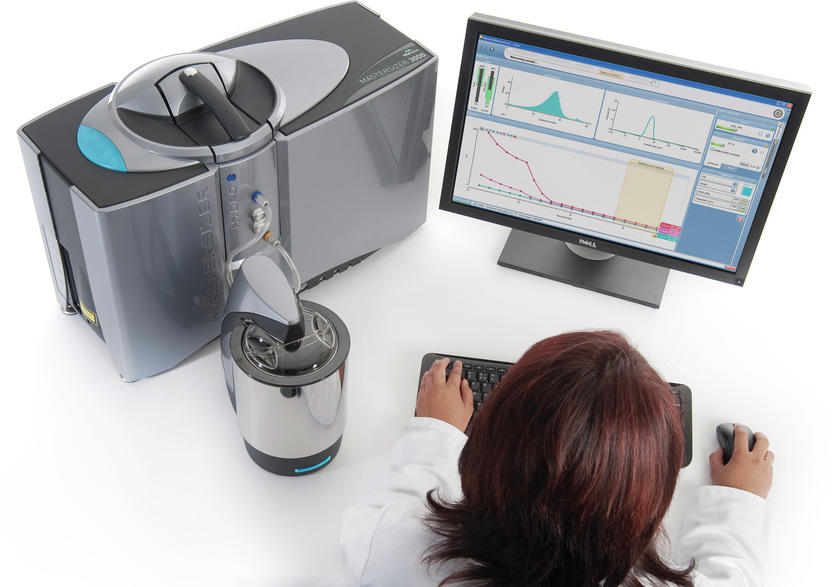

1 In the dry processing, the flour is finely milled, and then the large starch granules are separated from the smaller protein-rich particles by air classification based on size, shape and density. 6–8 In general, protein extraction processes can be classified into dry and wet methods. Numerous methods for the extraction of proteins from pulse flours are being studied to optimize the quantity while maximizing the quality. In recent years, they are being considered as alternative protein sources to replace animal and soybean proteins due to their higher protein content, lower cost, lower allergenicity and wider acceptability. 4 Pulses are rich in proteins, starch, fibre, vitamins and minerals. However, dry legumes or pulses, as a critical and inexpensive product, are fast emerging as a popular source of plant proteins in food. 3 Protein concentrates and isolates from soybean and wheat are widely used in the food industry. 1,2 In the food industry, plant proteins are used to replace animal proteins to meet consumer demand, improve nutritional quality, and maintain similar functionality and sensory characteristics ( i.e. Introduction Plant proteins are gaining more interest, across the globe, due to their wide range of applications in plant-based food systems. Such models could be extremely beneficial for the food industry to modulate processing for the development of desired pulse protein ingredients. Emulsion viscosity was more dependent on water holding capacity compared to any other factor. A decrease in interfacial tension was more favourable to lower destabilization. The regression model predicted that an increase in solubility, intrinsic fluorescence, water and oil holding capacities are more favourable to decrease emulsion particle size, while an increase in solubility, intrinsic fluorescence would lead to higher emulsion destabilization. Emulsions stabilized with concentrates were better or comparable to the isolates in terms of particle size, zeta potential, and microstructure. Canola oil (40 wt%)-in-water coarse emulsions, prepared with 2 wt% proteins and 0.25 wt% xanthan gum showed smaller particle size at pH 7 than pH 2, while the zeta potential, viscosity and gel strength were higher at pH 7. The higher protein content of the isolates was found to improve their water holding capacity. Interfacial tension of all faba proteins was lower than pea, while there was no significant difference between the concentrates and isolates. The protein secondary structure did not show a consistent difference however, much higher intrinsic fluorescence was observed for the soluble compared to the insoluble fractions. The concentrates produced by air classification had lower protein content but higher solubility in water compared to the isolates produced by isoelectric precipitation. The effects of different extraction methods on the structure–functionality and emulsification behaviour of pea and faba bean protein isolates, and concentrates were studied at pH 7 and 2, and a regression model was developed to predict emulsion characteristics based on protein properties.

0 kommentar(er)

0 kommentar(er)